Back to Home

Astron Power Supplies

Compiled, HTML'd and Maintained by Mike Morris WA6ILQ

Formerly Maintained by Robert Meister WA1MIK

|

Back to the Astron Index page Back to Home |

Introductory Information on Astron Power Supplies Compiled, HTML'd and Maintained by Mike Morris WA6ILQ Formerly Maintained by Robert Meister WA1MIK |

|

You probably came to this web page because you have an Astron supply that has problems. On this web page we present some cautions, solutions, modifications, repair and rebuild tips.

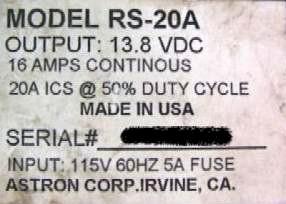

The above model tag shows that an RS‑20 is rated by Astron at 16 amps continuous duty. Don't believe it!!! My personal opinion, which a number of my repeater-building friends share, is that you never load an Astron at over one-half its advertised rating and anything over 25% requires a fan on the heat sink. In other words, an RS‑50 is only good for about 20 to 25 amps in continuous service, and one knowlegeable person suggests that an RS-50 is only good for about 12 amps continuous duty!.

Astron's use of the term "ICS" on the label DOES NOT stand for "Intermittent Commercial Service" (a description that has an industry standard meaning), instead they say it stands for "Intermittent Communications Service" (Astron's own invention). Astron marketing explains that by saying that in normal operation the user listens (i.e. low current) a lot more than he / she talks (high current). They say this gives time for the heat sink (and pass transistors), transformer, etc. to cool down.

In other words, Astron is marketing peak intermittent current capacity and counting on a low duty cycle for their product to survive everyday use. Due to the fact that Astron products have repeatedly failed, a number of system owners have abandoned Astron as the primary supplier of their repeater power supplies - most have switched to Samlex SEC-series or Duracom supplies (SEC-40, SEC-60, SEC-80 or SEC-100). This includes your page maintainer... at the 9 sites he helps maintain there are no Astrons in commerical service... 80-90% Samlex and 10-20% Duracom.

The linear Astron supplies are based on the common "723" series regulator chip (originally designed and sold by Fairchild Semiconductor in the 1970s as the µa723). The basic Astron linear supply design is straight out of the data sheet and application notes. At the time of this writing at least six different manufacturers second-source the 723 chip. I've seen Astrons with LM723s from National Semiconductor, the MC1723CPs from Motorola, and both the Signetics and Texas Instruments versions. In the Motorola Semiconductor model number structure, the trailing CP indicated commercial temperature range and a plastic package (as opposed to military and ceramic), but the CP is the same internals as a 723C. For simplicity in this writeup I'm going to use just the LM723 number no matter what manufacturer made the chip you have in your particular Astron. Most of the major chip reference web sites have the data sheet and applications notes, and the theory and design information you will find there is as true today as it was when the chip was introduced... Starting with the design notes is a good idea. There is a downloadable copy of the data sheet and an application note later on on this web page, plus PDFs of a few relevant magazine articles.

Note that the common LM723 chip used by Astron is the less expensive temperature derated version - the performance is only guaranteed over a 0°C to +70°C temperature range (the so-called "commercial temperature range"), instead of -55°C to +125°C (the "military temperature range"). In every Astron I've been inside the chip is in a socket... If your Astron is going to a mountaintop repeater site that gets anywhere near freezing in the winter I'd swap the chip with one that is guaranteed below 32°F / 0°C... Yes, minus 60°F / -55°C is overkill for the average repeater, but your only choices are "Commercial" with a 0°C rating, or "Military" with a -55°C rating. Given that situation, ordering a mil-spec chip is the simplest way to get one that is rated below freezing... and you can use the original 723 that you removed from your Astron somewhere else.

Before you start debugging your Astron, I suggest that you read the following articles in the "Power Supply Design and Theory" section below:

There are prices mentioned in a few places on these Astron web pages. Use them as guidelines only as they were relevant at the time of the initial writing of these pages (around 2004). Some were changed during updates, some were not.

Introductory Information on additional Astron linear power supply topics can be found on these additional pages below.

Power Supply Design, Theory and Repair

Miscellaneous Data Sheets:

Contact Information:

The author can be contacted at: his-callsign // at // repeater-builder // dot // com.

Back to the top of the page

Back to the Astron index page

Back to Home

This page originally created in August 2000 by Kevin Custer W3KKC

Totally rewritten with permission on 10-14-2004 by Mike Morris WA6ILQ

Copyright © 2000 and and date of last update by Repeater-Builder.com

The Astron logo/image is a registered trademark and is used on these Astron pages with permission from the Astron Corporation.

The schematic images are copyright © Astron Corp. Each one is dated on the individual drawing. No copyright infringement is intended. If Astron had the schematic library on their web site we wouldn't need to.

This web page, the hand-coded HTML on it, this web site, the information presented in and on its pages and in these modifications and conversions is © Copyrighted 1995 and (date of last update) by Kevin Custer W3KKC and multiple originating authors. All Rights Reserved, including that of paper and web publication elsewhere.