Go to Tech Index

Back to Home

|

|

Basic Information On Temperature Compensation and Modulation Capability

for Channel Elements, ICOMs, and TCXOs

Plus some tips on ordering crystals

Compiled from contributions from

Eric Lemmon WB6FLY (SK),

Jeff DePolo WN3A,

Robert Meister WA1MIK (SK),

Doug Marston WB6JCD (SK),

Jeff Kincaid W6JK

Neil McKie WA6KLA (SK),

Kevin Custer W3KKC,

and Mike Morris WA6ILQ

Compiled, HTML'd and Maintained by Mike Morris WA6ILQ

|

|

|

Concept:

This page deals with the subject of replacing the crystal in any

type of Temperature Compensated Crystal Oscillator (TCXO), be it a

Motorola "Channel Element", a GE "Integrated Circuit Oscillator Module"

(commonly called an ICOM), or an RCA TCXO. Here we're going to use the

term "element" just to make writing this article easier.

We're going to describe the problems that can arise by rebuilding

them yourself. Most hams are frugal (some are downright cheap) by

nature, always wanting to save a nickel anywhere they can. Replacing

the crystal in the precision frequency determining element is a

necessary task when taking a crystal controlled radio and moving it

from one frequency to another. Money can be saved by recrystaling the

elements yourself, but there are problems that can arise when doing so.

Many folks don't know about the issues when buying a $10-$15 crystal

and stuffing it into the element themselves. Sometimes the issues

are with the crystal itself, sometimes they are with the element,

and lastly, both can contribute to the end result.

One comment I have heard over and over again - places like Sentry and

International do not just recrystal an element, they remanufacture it!

Unfortunately, the crystal houses and several manufacturers manuals refer

to the remanufacturing process as "compensating" the element despite the

fact that temperature compensation is only one factor in the remanufacturing

process.

A very perceptive comment on rebuilding elements, from an email to

Repeater-Builder from Eric Lemmon WB6FLY:

...There still seems to be a tendency to seize upon temperature compensation

as the primary reason for sending the element to a crystal house, and that is not

the case. In fact, the temperature compensation is not the most important

issue at hand.

I believe that "compensation" of a crystal in an element comprises a number of actions:

- Receive and Transmit elements: Ensuring that the final (after aging) center frequency

is within the range of the warping adjustment.

- Receive and Transmit elements: Ensuring that the output amplitude exceeds the minimum

specified AC voltage value.

- Receive and Transmit elements: Ensuring that the center frequency versus temperature

remains within specification.

- AFC receive element: Ensuring that the output frequency shifts the correct direction

and amount with the change in AFC voltage.

- Transmit elements: Some element designs have the modulator inside, some do not. On

those that do, the rebuilder must ensure that the output frequency can be deviated properly

with the specified modulation voltage.

- Transmit elements: Likewise, on modulating elements they ensure that the deviation is

symmetrical about the center frequency.

- Receive and Transmit elements: Ensuring the spectral purity of the output signal under

all extremes of temperature, AFC voltage (on AFC receive elements) and modulation (on transmit

elements).

- Receive and Transmit elements: Ensuring the crystal is "active" enough - that the output

level (RF amplitude) meets specification.

It should be obvious that few, if any, of the above actions can be performed on a crystal

by itself, since most of the components that directly affect the operation of the crystal are

not in the crystal. In other words, whether or not the radio is in a temperature-controlled

environment is hardly the point; it is more important that the crystal perform properly in

the oscillator circuit. That's hard to verify if you don't send the oscillator circuit to

the crystal house!

Notes on Temperature Compensation:

The first thing to realize is that the crystal frequency varies with

ambient temperature. Period. It's a simple law of physics. The frequency

the crystal oscillates at is also determined by the circuitry around it,

and the values of the components in that circuitry. The crystal manufacturers

even have a name for this characteristic - you will see references to

a crystal "operating into a 32pF load" (or some other number).

If the load value changes, the frequency changes. The method used in

temperature compensating a crystal is to deliberately use other temperature

sensitive oscillator components to vary the capacitance across the crystal

and the load on it, thereby counteracting the temperature-caused change

in crystal frequency. The temperature sensitive components are carefully

chosen so they exactly counteract it, and over as wide a temperature

range as possible.

A bit of physics: Crystals are made by putting a slab of polished

quartz between two conductive plates. Picture a sandwich made from

two pieces of bread and a slice of cheese in the middle - the slices

of bread are the plates, and the cheese is the quartz crystal. Raw quartz

has a grain, just like wood, and the angle of the cut relative to the

grain has a lot to do with the characteristics of the finished crystal. There

are several preferred angles to cut quartz for crystals, and the companies

that do communications crystals use the cuts that are optimized for

frequency stability. Companies that make crystals for digital circuit

clock oscillators use cuts that maximize the number of crystals per slab

(i.e. make them to a price target) and rely on the fact that any

frequency error is divided as the crystal frequency is divided down

to a target frequency. A drift of 100 Hz on a 1 MHz crystal

divided down to 10 pulses per second is a drift of one millisecond. You

will never see a 1 ms drift (even if it was 10 times that - a full

kilohertz) if that crystal is in the digital LCD clock on the wall.

This situation is the exact opposite of the communications world where

crystal frequencies are multiplied up to a operational frequency and every

frequency error is multiplied as well. This is how the modulator in an FM

transmitter works - a UHF transmitter using a 12 MHz crystal multiplied

36 times only has to wiggle the crystal frequency about 140-150 Hz

to get a full 5 kHz deviation. A 900 MHz transmitter with a

times 48 multiplier needs a 50 Hz wiggle to get a full 2.5 kHz

deviation. 50 Hz is more drift than most crystals have during warmup!

In short, you need to get your crystals from a company that understands

the technical requirements of the communications crystal as opposed to a

microprocessor (or timepiece) clock crystal, and from one that operates

towards a quality target, not a price target.

Note from WA6ILQ:

By the way, if your crystal is in a totally temperature stable environment, then

no temperature compensation is needed. This is why two-way radios in the 1940s

through the 1970s used crystal ovens - small plug-in housings that kept the

crystal at 80 degrees C (about 175 F).

Repeater sites are a whole different situation - I've personally seen cabinet

interior temperatures as low as -20 degrees C (-5 F) and as high

as +50 degrees C (+130 F) at sites that had no environmental controls.

I've also seen sites that have air conditioning / heat pump systems

(i.e. cooling, heating and humidity control) that kept the equipment within a

10 degree window year around. And note that just because the building has a

nice environmental control system that does not mean that you can scrimp on

the crystals or the elements - the temperature inside the radio, where the

crystal or element is located, is often much warmer and more widely variable

than the room temperature. The power supplies make great heaters and the

RF shields make great airflow shields too.

So from the above, you can see that the performance of the element

during extreme temperature swings is only as good as the crystal

installed in it and the compensation that was done at the time

the crystal was installed in the element. The element only achieves its

specified stability if the element is matched to the crystal. If

the crystal tends to swing upwards in frequency as the temperature rises,

the element has to swing lower, and by the same amount. Likewise, if it

swings down in frequency, then naturally the element has to swing upwards.

And in order for the two swings to cancel, they have to be exactly matching.

Another way to think of this behavior is "temperature to frequency tracking".

The desired end result is a crystal and element combination that maintains

the specified frequency and stability, and operates properly in the circuit

for which it will be used, and does it from one temperature extreme to

the other. And the previous discussion is only concerned with the

oscillator - and has not touched on if the crystal can be modulated, or if

the modulation is equal above and below the center frequency, or having a

stable output level, or a pure signal.

When placing a new crystal in an element yourself, you take the chance

that it may or may not work correctly (and the odds are stacked against you).

When someone re-crystals an element, it's a game of chance if the values of

the existing compensation parts that were installed when the element was

manufactured (or was last recrystaled) will accurately track the new crystal

to specification. , There's a chance it could, there is also a chance it could

make it worse! Many hams do this with success, others have problems.

However, the average ham does not have the test equipment to validate the

new combination of crystal and element.

Note from WA6ILQ:

Personally, I'll recrystal an element for bench test

elements, my personal base or mobile stations, however anything that goes

at a commercial site or on a mountaintop goes to International. This is

especially true about the one site that is inaccessible, except by

helicopter, from first snowfall to late March or early May. And any element

for a radio that is on a commercial, Red Cross, GMRS, public safety or military

channel goes to International.

Many folks will choose to recrystal their elements themselves to save money,

and, in some situations, that's fine. However, just because you have an element

rated at 5 Parts Per Million (PPM) (i.e. a Motorola blue element or a GE

"5C" element) doesn't mean the element with your new crystal

inside it will provide you with 5 PPM stability. As you now realize, when

you change the crystal in an element, you will almost always need to make other

component changes inside the element to ensure its designed temperature stability

(i.e. to "mate" the crystal to the element). And it's more difficult with a

Motorola gold element or a GE "2C" ICOM - a 2 PPM

element (the ones required in the GMRS service), and even worse on

a 1 PPM element used at 800 MHz, 900 MHz or 1200 MHz.

Note from WA6ILQ:

And what was the source of the element?

I've seen the following scene way too many times: Joe Ham finds a retired

GE or Motorola station in surplus, and buys it. He carts it home then

discovers that the station has no elements. None of his friends have any

available (even if they know what they are). So he shops on eBay, or has a

friend pick up a set at Dayton. He orders crystals from South Driftal Inc

(or some other lowest-price place) and mounts them in the elements. He fires

up the station and has nothing but troubles.

So what's wrong?

1) He does not know if the station had problems before he bought it. It may

have had more bench time than in-service time. I've also seen used stations

where every major assembly had different problems (i.e. a good spare station

had been progressively cannibalized to fix other stations, and all the bad

assemblies put into that one cabinet that was then sold to an unsuspecting

ham... I can see the ebay auction now - "station originally purchased as a

spare but never placed in service!").

2) He does not know if the elements are good. They may have been at Dayton

because they were bad and someone wanted them off of his shop shelf.

3) He does not know if the cheap crystals even work in that circuit, if they

are temperature stable and if the transmit element can modulate adequately

and symmetrically.

This is why time and time again you see the comment on

the Repeater-Builder mailing list:

always get the old elements with the station and verify the operation of

the station on the old frequencies. If you can get an extra set of elements

so much the better. A half hour with a dummy load and a service monitor

(or a good signal generator and a spectrum analyzer) will let you know if

you have a good radio BEFORE you go setting it up on amateur channels. Then

take some KNOWN GOOD elements (maybe the original elements) and send them

to the crystal house for recrystalling. They will be tested for proper

operation, including output level and spectral purity, before your new

crystals are installed, and then tested again afterwards before the actual

temperature compensation process. In other words, your elements are first

tested on their existing frequency / frequencies, then remanufactured

on your new frequency / frequencies then tested to make sure they meet

original specifications.

Back to elements and compensation...

Note that the compensation components in the element are dependent on

the characteristics of the individual new crystal, and those characteristics

have to be measured (with extreme temperatures) after the crystal is made.

The components are then selected by hand and installed. Hence, this has

to be redone whenever the element is recrystaled. Most of the cheaper

suppliers build a crystal, install it, and change the primary parallel

capacitor so the channel element resonates "on frequency" with the trimmer

device centered. This one new component (the capacitor) has nothing to do with

temperature tracking or stability, modulation capability, modulation symmetry,

proper output level (amplitude) or the spectral purity of the output signal.

Just for reference, the term "modulation symmetry" means that for a given

modulating audio voltage that the carrier shifts an equal amount above and

below the idle carrier frequency (i.e. in FM, not AM).

Speaking of modulation capability...

A crystal with the wrong cut may not exhibit enough rubberiness

for full and undistorted deviation to occur (yes, we invented the word. Can you

think of a better one?). This situation happens when a crystal vendor cuts a

crystal for absolute stability (by making the crystal stiff) and doesn't realize

that it will be used in an FM transmit element. Even if the crystal does make enough

deviation, it may not swing the same amount on each side of the center frequency,

or the modulation may otherwise be distorted. International Crystal and Sentry

are the only companies (and ICM bought Sentry in January 2005) that I know of that

actually test the modulation capability and ensure modulation symmetry in

their finished elements. ICM and Bomar are the only companies that I know of that

actually change the temperature compensation components (capacitors and resistors)

to properly temperature compensate the element, and then test for

the five characteristics mentioned above. The symmetry is very important as

poorly made or poorly compensated crystals don't have a symmetrical response

to deviation voltage, causing the average center frequency to shift during

modulation. In other words, you may be on frequency with no audio, a little

off frequency at 900 Hz deviation, a little more off frequency at 2 kHz

dev, and a lot off frequency at 5 kHz dev.

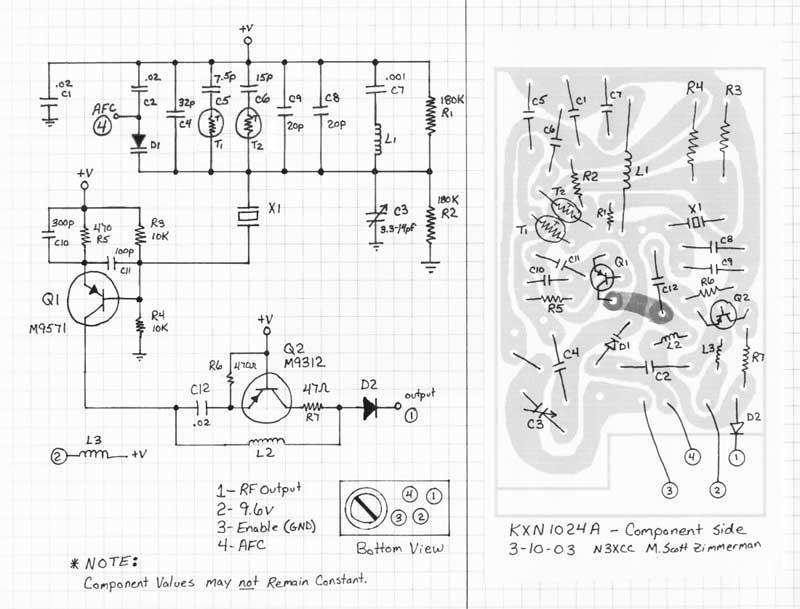

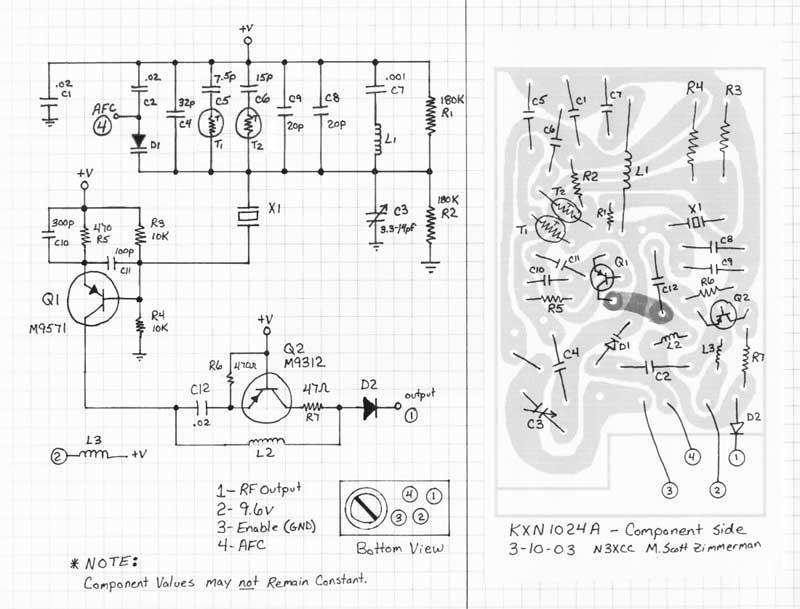

The actual schematic of the RCA TCXO or the GE ICOM is not in the

manuals (the schematic in the LBIs is simplified, and on it the frequency

compensation area is just a block diagram), but the schematic of the

equivalent Motorola Channel Element is below, courtesy of the reverse

engineering capability of Scott Zimmerman N3XCC, of Repeater-Builder:

Look carefully at the schematic. Q1 is the oscillator. Q2 is a

buffer-tripler. X1 is the crystal). Go north from there, and across

to C3, the trimmer. Then find L1 and C7. Nothing north of the crystal

but C3, L1 and C7 is needed to make an oscillator. Now find the

AFC pin, C2, D1, R1 and R2. Those components are all that is needed to make

the frequency move with the AFC voltage. Everything else that is north

of the crystal is compensation.

Here's a dissertation on the

General Electric (GE) MASTR II ICOM.

To deal with temperature stability, the crystal and element must be heated

and cooled under strictly controlled conditions, and the frequency must be

measured accurately at each temperature extreme. New compensation components

are then chosen and installed in an attempt to minimize the overall frequency

change of the assembly. This must be repeated until the desired stability is

achieved. It's a trial and error process; each heat-and-measure then

cool-and-measure then component-swap cycle could take several hours, so the

worker is working on or testing another element while the first one is

heat-soaking or cold-soaking... in fact he or she may be rotating as many as

a dozen elelments across his/her bench and through the chiller and the oven

at any one time. And remember that in most electronic circuits the intent of the

designer is to select components that have a minimal effect from temperature

changes - here the objective is the exact opposite in that the components in

the compensation area are specifically and carefully chosen for their changing

characteristics at varying temperatures.

Once the temperature compensation process is complete the element is tested

again for proper RF output level and spectral purity on the new frequency. If it

is an AFC receive element they test it for proper direction of shift with AFC

voltage, plus the sensitivity to that voltage and proper range.

If it is a transmit element and has an internal FM modulator they test it for

modulation sensitivity, symmetry and distortion under ambient temperature

and at hot and cold temperature extremes.

When you are ready to recrystal an element and are calling around to get prices,

you need to ASK what each company does when "compensating" an element. To

recycle an old line, you can't compare fruit unless you care comparing apples to

apples and oranges to oranges.

Not all will go through the time-consuming process of hand-selecting components and

thermal cycling in the two environmental chambers (one for heating, one for

cooling, and both use air drying equipment so that there are no condensing humidity

droplets to cause problems). Considering what you are going to spend on the entire

repeater, paying a little extra for a professional top quality crystal house to

manufacture the crystals and do the compensation is definitely worth it. If you are

serious about your repeater, especially if it's going to be located in a hilltop

building with no climate control, do yourself a favor and send the element(s) back

to the crystal house and pay to have them compensate the element to the crystal. After

all, those people have the thermal chambers, the air drying equipment, stock the wide

variety of the proper temperature sensitive capacitors and thermistors, and have the

expertise to use all of them to their best effect because they do it 8 hours a

day, 5 days a week, for 52 weeks a year.

Crystal and Element Specifications:

Individual crystals and channel elements are built to certain stability specifications,

measured in Parts Per Million (PPM), and refers to how many Hertz a crystal or element

can drift (vary in frequency) with changes in temperature from a known reference

point. In a GE MASTR II, that's 80 degrees Fahrenheit. A 5 PPM crystal / element

combination can drift 5 Hertz for every million Hertz of operating frequency. So,

a 146.000 MHz element can drift 146 times 5 which equals 730 Hz. This means a

146.000 MHz element can vary plus or minus 730 Hz and still be within the plus

or minus 5 PPM specification. Holding to this same specification, a UHF transmitter

operating on 445.000 MHz can vary 2,225 Hz and still be within specification (but

an experienced ear can hear someone that is 1 kHz off frequency). And remember

that the plus and minus 2,225 Hz tolerance at UHF is only 61.8 Hz

at the 12 MHz crystal frequency (due to the times-36 multiplication)... and it's

even tighter if the exciter uses an 8 MHz or a 6 MHz crystal (about 30 Hz).

Yes, that means that your 12 MHz crystal oscillator signal can drift at most

about SIXTY-TWO HERTZ each direction of the center frequency from the coldest

winter night to the hottest summer day and stay legal at UHF. Warmup drift in

most equipment is more than that.

The tighter frequency tolerances and 2.5 kHz devaition limit on

900 MHz makes it even worse - one 927 MHz repeater transmitter

that I worked on has a multiplier of times-48. One PPM at 927.5 MHz

is 927.5 Hz. Divide that by 48 and you have 19.3 Hz. This means

that your 927 MHz repeater transmitter oscillator has to stay within

20 Hz of frequency ! And the 2.5 kHz deviation at 927 with

a times 48 multiplier only needs about 50 Hz of wiggle for full deviation.

Yes, a drift of 50 Hz will push the transmit signal right out of the

bandwidth of the user's receiver.

From the above, the FCC rules notwithstanding, it's plain to see why people

choose 2C elements (0.0002% ) for UHF repeaters and mobiles (resulting in a maximum

of about 900 Hz variation) and 1C for 800 and 900 MHz (800 Hz or

900 Hz variation). It's also plain to see why you should spend the extra money

and have a reputable crystal house redo your repeater elements so they are properly

rebuilt and temperature compensated. Also remember, you get what you pay for.

I have heard the complaint many times "ICM wants $50 to replace the crystal in the

element". Now you know why, and that it's not all that simple. It's more than just

mounting and soldering the crystal, it's ageing the new crystal plus many hours of

heating, measuring, cooling, measuring, installing compensation components, and

repeating the cycle until it's absolutely right. And then testing for modulation

symmetry, modulation sensitivity, minimal modulation distortion, adequate RF output

level, output purity, AFC voltage sensitivity and range.

So go ahead and buy the crystal for $20... Can you do the rest at home

for $30 more ?

Especially considering that a round trip to your repeater site (depending on

where it is) may take six hours and cost a tank of gas ? Do the arithmetic.

For me a round trip to one site will cost 2/3 of a tank of gas, and a tank is 20

gallons. A trip to a different site requires me to coordinate schedules with another

gentleman who has a 4x4 truck - a round trip there costs about 30 gallons plus

meals. How many round trips will it take to equal the cost of having International

rebuild an element?

An emailed note from WA1MIK: I recently sent two Motorola MICOR

0.0005% receiver channel elements to ICM. They charged $19.95 for each crystal

and $30 to install, temperature-compensate, and test each element. The entire

process should take about a month, and more than half of that would be devoted

to the compensation and testing phase.

(Follow-up: elements sent in 1/19/07, received back 2/15/07. Worked perfectly.)

Another emailed note: In mid 2009 a pair of rebuilt UHF 2C ICOMs was

around $180, including tax and shipping.

A third emailed note: In early 2010 a single rebuilt UHF 2C ICOMs was

quoted as $83, plus tax and shipping.

Don't take the above quoted price as an absolute - redoing a 0.0005% element

(i.e. a 5C) is the least expensive, an 0.0002% element (a 2C) costs more, and

a 0.0001% element (a 1C) (used at 800 MHz, 900 MHz or 1200 MHz)

costs the most.

Comments on crystal aging:

Most new crystals will drift downward in frequency in the first 6 months of

operation (but some will go up) - this drift is very visible on UHF and can be

seen even on 28 MHz. This drift is due to the crystal "aging", and is quite normal.

In the mid 1980s crystal manufacturers adopted a technique called "pre-aging", where

they cut the raw quartz crystal material into blanks, then run the blanks in a power

oscillator circuit under very elevated temperatures for several weeks. Then this

pre-aged material is processed into crystals. Once the crystals are cut close to

frequency they run them in a heat / cool cycle for a week or so, then the

final manufacturing process puts them on frequency and in the metal case. This

technique produces a finished crystal that might age an additional 3 to 5 kHz (at

UHF) total, if that much. Then, if the finished crystal is headed for a channel

element, it is installed, compensated (which includes a number of additional

heat / cool cycles), tested, and shipped. Note that rebuilt elements get

much more run-time and more heat / cool cycles than plain crystals. This

is one reason why compensated elements don't age as far as individual crystals.

In closing, do not be surprised if a properly manufactured crystal (or a

remanufacturered element) drifts a little in the first 6 months, but it will

not be very much.

From WA6ILQ:

Even if your brand-new UHF crystal drifts as much as 7 kHz (on the UHF frequency,

not the fundamental) during the first 5 to 6 months of operation, it does NOT mean

that the crystal is defective. Just plan on resetting the frequency a few times in

the first 6 months of continuous operation (which may take a lot longer on a transmit

crystal since it doesn't get as much "run time" as a receive crystal). Once the crystal

ages it will settle down.

As a personal example of the above aging, back in the early 1980s I moved a UHF Motrac

repeater from GMRS (467 / 462 MHz) to the 443 / 448 MHz range.

The newly crystaled receiver drifted 11 kHz in the first 5,000 hours of operation

(four adjustments of about 5 kHz, 4 kHz, 2 kHz and 400-500 Hz across six to seven months),

and hasn't budged 800 Hz in the 20-25 years since. Interestingly enough, when the

crystal was placed in service the adjustment was almost at one end, and when the frequency

stabilized the adjustment was very close to the middle of the range. You can avoid this

by having a "test fixture" on your bench operating 24x7 to "burn in" the

crystals / elements while you work on some other part of the system that you

are building. The channel element / ICOM "test fixture" can consist of just a

a channel element or ICOM socket (or two), a power supply (which can be nothing

more than a 9 to 10v DC "wall wart" transformer),a 3-terminal voltage regulator, and a

resistor (as an output load for the oscillator or element). If you are running crystal

based radios then it can be just an extra oscillator or exciter board, the wall wart

and a load resistor. Make sure the element is seeing nice clean stable DC of the correct

voltage. All you are after is a way to run the element(s) (or crystal(s) full time when

you aren't in the shop.

My personal method is to set a brand-new crystal / ICOM / channel

element on frequency in the test fixture and wait a few days and see which direction it

heads as it ages (90% have gone downward in frequency). I then set it back on frequency

and a little further in the same direction so the next bit of aging brings it back towards

center of channel. Once the new repeater is finished I take it to the hilltop and mark my

calendar - I then check the frequency at a week, two weeks, a month, at 2 months and at 6

months, plus any other opportunities when the service monitor is handy.

Notes on Ordering Crystals:

See the Suppliers Page for a list of

the crystal houses that really do Element Remanufacturing and Temperature

Compensation.

Thanks to Neil McKie WA6KLA (SK) for letting me plagiarize his crystal ordering

rules. He developed them from personal experience in over 35 years in commercial

2-way radio at a mix of privately run and government shops. The notes I'm typing

these from are dated 1983.

Crystal ordering rule #1: When I make an order I call the crystal house on

the phone and verbally order the crystal(s) and give them a credit card number

to place the charge against. They give me an order number (which I repeat back

to them), and send the order to production that day. While they are grinding

the crystal(s) I'm boxing and shipping them the element(s). On each order I always

ship them one extra element - there have been times when they've found a dead

or otherwise bad element, and I've always received the spare back with the

remanufactured element(s) (and it beats waiting the extra time while you locate

and ship them another element). If I'm sending over ten elements of the same

type I include two extras. If I am having them do multiple types of elements

(for example, both a receive and a transmit element) I include a spare of each

type. There have been times that a single order has been for eight or nine

frequencies and sent them a dozen elements. And I include a note in the box

with the elements noting the order number, listing the channel elements and

the frequencies I am ordering, and explaining why the extra element(s).

I also put a piece of masking tape on each element I am sending them with the

order number and the new frequency written on it in ink, just in case the note

gets separated from the box of elements. All it takes is something like

"Order # 65-12345, rebuild to receive on 444.000 MHz", "Order # 65-12345,

rebuild to transmit on 449.000 MHz" or "Order # 65-12345, Extra receive element

in case one is bad".

In several hundred orders Neil never had a problem with this procedure.

And both of us always received every one of the extra elements back, occasionally

with a "NG" (not good) note taped to one of the elements.

Crystal ordering rule #2: I never give them the crystal frequencies

(i.e. let them figure them out) - I give them the target frequencies (receive

and / or transmit), the radio type and the channel elelment model

number (i.e. Mitrek KXN1086B element to be moved to 449.000 MHz) and

on ham radio orders I always mention the receiver injection direction,

even if it's unchanged (note that in most cases when you move a GE MASTR II

receiver from commercial high band to 2M or from commercial UHF to 440 you

will want to flip over the injection from low side to the high side). The

rock chippers need to know this!!

Even on 220 MHz MICOR receiver conversions

I just tell them that I want it to receive on a certain frequency, the

multipler used to be 9 and is now 12, I want low side injection, and I

still let them caculate the crystal frequency. One result of this policy

is that the correct channel frequency is stamped into the crystal case along

with the crystal frequency.

From WA6ILQ:

The only time I've told ICM what frequency to cut the crystal to is the time

I had them take a UHF 2 ppm element and put a 10.000 MHz crystal in it,

compensate it and bypass the internal tripler (and if I'd had a 1 ppm element

I'd have used it). I installed the resulting custom element into my Yaesu YC355D

counter as a replacement for the the 10 MHz time base reference. My counter

came with a bad crystal and it drifted all over the place... The decision was a

no-brainer... a custom element from International cost about $5 less than what

Yaesu wanted just to estimate the repair. My own testing after the mod was installed

revealed that the element was dead on from the coldest temperature my kitchen food

freezer could do to over 125 degrees F (50 degrees C). Supposedly the

counter wasn't an end-user repairable piece of equipment despite the fact that

the design was straight out of Popular Electronics magazine (and that article was

based on a Texas Instruments applications note). Yaesu wouldn't sell me just the

crystal, they "had" to install it on their bench in their shop). Sorry, Yaesu... the

channel element mod was a lot cheaper and the counter became a lot better piece of

equipment (much more accurate both in short term and long term).

Crystal ordering rule #3: Never, ever ask the crystal house to push the delivery

time. Plan on four weeks, occasionally five (if the crystal house has a large bunch

of orders) to deliver properly cut and aged crystals (or rebuilt channel elements).

If it shows up in three weeks, say a thank you prayer to your personal higher power

and add a bit extra to the sunday collection plate in thanks. If you absolutely have

to get a rush crystal, order both it AND A REGULAR CRYSTAL AT THE SAME TIME.

Why?

The reason is best given in a story... this dates from the days of GE MASTR Pro

radios with separate crystals in sockets (i.e. not in channel elements or ICOMs) but

it is as true today as it was then.

Neil told me about the time he did a mountaintop service call on a dead community

repeater and discovered that the receiver crystal was bad. He had fought this

battle before... He got his lineman's phone out of the service truck, clipped

across the phone line at the repeater site and called International Crystal right

from the repeater site (and as he tells the story - and note this is pre-caller-ID

days, you know that you've been in the business too long when the order desk lady

at International recognizes your voice, calls you by name, and asks if it's a

company order or a personal ham radio order).

He ordered both a rush crystal and a regular crystal. The rush crystal arrived via

airmail special delivery in five or six days. Neil drove to the site, installed it

and set it to frequency. The next day he drove to the site and reset the frequency.

Two days later he drove to the site and reset the frequency. And every three or four

days for the next three weeks either he or one of the other techs was at the site

setting the frequency. THIS IS WHAT UNAGED CRYSTALS DO - THEY DRIFT. When the

replacement regular crystal arrived (exactly four weeks and one day from the day

he ordered it) Neil was very happy to drive to the site and install it, and set

it on frequency (and yes, it required a couple of resettings before it stabilized).

Then he drove back to the shop, put the rush crystal in a spare receiver and let it run.

And run. And run. Months later it was still drifting! Neil took a

three pound sledge hammer, beat that crystal paper thin and gladly tossed it in the

trash. The rush crystal bought the company three weeks of income from the community

repeater airtime, but cost a a couple dozen service trips, however it wasn't usable

even with months of 24x7 cooking time!

The lesson? Give the crystal house time to do a proper job. UNAGED / RUSHED

CRYSTALS ARE JUNK.

The other lesson? If your day-to-day income depends on crystal-based devices (like a

bunch of community repeaters) then you need to have ready-to-go spare

receivers/exciters/crystals/elements on the shelf.

|

The following was extracted from a discussion on the repeater-builder

Yahoo! Group (reproduced with each of the participant's permission):

What exactly are ICM and other crystal manufacturers doing when they "compensate"

or match an element with a crystal to get it netted on frequency?

I've had mixed success. Some crystals and elements tune on frequency just fine,

while others don't. I've had mixed luck padding extra capacitance on MICOR elements,

but Mitrek elements use the inductor instead.

For example, I have a KXN1052 that's 20 kHz high after dropping in a new crystal.

I can pad the trimmer, but then the element won't produce more than 3 kHz of transmit

deviation.

What's their secret? The only thing in the element is resistors and capacitors!

I'm sure those of us capable of working on a repeater are capable of changing a few

components.

= = = = = = = = = = = = = = = = = = = =

Each channel element, regardless of the manufacturer, contains a number of resistors,

capacitors, and perhaps a few inductors. The capacitors have specific TCs (Temperature

Coefficients) that are chosen so that the capacitance variation with temperature change

is exactly complementary to the reaction of the crystal. When performed correctly, the

capacitors change value with temperature just enough to cancel out the frequency drift

of the crystal.

However, a full compensation of the crystal holder (channel element, ICOM, etc.)

includes more than temperature compensation. The technician also verifies that the

crystal can be set exactly on frequency with the included trimmer, that the output

amplitude meets the minimum specification, and that the crystal is "rubbery" enough

to be modulated to the required deviation level, and the modulation is equal on both

sides of the idle (carrier) frequency.

As you might expect, full compensation of a channel element to a particular crystal

is an exacting and time-consuming process. That's why ICM charges more for the

compensation ($30) than the crystal costs ($20).

When a radio user orders just the crystal and puts it into a handy channel element,

the components inside that channel element may or may not match the characteristics

of the new crystal. As you and many others have discovered, the new crystal could be

such a poor match to the channel element that it may be impossible to get it to operate

on frequency. Even if you can add or remove some shunt capacitance to tweak the crystal

to frequency, that shunt capacitance is not temperature compensated. It may work fine,

and it may not.

Both Motorola and General Electric operated their own crystal manufacturing facilities

for many years. Since each company had complete control over the making of both the

crystal and the channel element that contained it, they could evolve the processes to

optimize performance and longevity. Let's say that Motorola found that their MICOR

channel elements worked best with crystals that were made for a 25 pF load rather than

a 30 pF load. If you have one of these original MICOR channel elements that you want to

re-crystal, it is likely that ICM, Bomar, or Crystek will ship you a nominal crystal,

since they have no way of knowing that your channel element is not nominal but has

already been compensated to the original crystal, which may have a non-nominal load

capacitance. How can they know, if you don't send in the channel element? Also, since

the crystal house never had the chance to test your channel element first, they have

no obligation to make changes to your crystal if it doesn't work properly once you

install it.

Given that a full compensation is a one-time charge, I personally have every

hilltop crystal I buy given the full compensation in a channel element I send to

the crystal house. I think it's a prudent investment. Not everyone agrees...

= = = = = = = = = = = = = = = = = = = =

Ok, but back to my original question: if I send an element to ICM to be re-crystaled,

do they cut the crystal first to "their" standards, then modify the element to make it

work, or do they measure the element first in some fashion, then cut the crystal to

match the specific element's characteristics?

= = = = = = = = = = = = = = = = = = = =

To the best of my knowledge, the crystal is always manufactured first to meet ICM's

nominal specifications for a stock element, and the channel element compensation

components are then modified as necessary to perform satisfactorily with that crystal.

= = = = = = = = = = = = = = = = = = = =

And don't forget, a channel element or ICOM that was previously compensated for

another crystal may work poorly or not at all with a new crystal. If the crystal house

does not have the element in their hands, they have no choice but to make your new

crystal to "nominal" specifications. And that is the problem, because none of

the used channel elements or ICOMs are a "nominal" oscillator- every one was

individually customized for the previous (probably original) crystal.

= = = = = = = = = = = = = = = = = = = =

The following was extracted from an International Crystal OEM crystal catalog:

ICM can recrystal customer supplied oscillator modules (channel elements) used

in most modern commercial two-way communications equipment. The service we offer

includes the following steps:

- Testing the element upon receipt

- Removing existing crystal

- Installing new crystal

- Checking RF output and trimmability (where applicable)

- Zeroing to center frequency (where applicable)

- Testing for accuracy over specified temperature range (where applicable)

- Relabeling element for new frequency

The oscillator modules (elements) are checked for proper operation when received.

If repair is needed (transistor, capacitor, etc.), it will be replaced at a nominal

charge. An oscillator module that has been damaged and/or unrepairable will not be accepted

for frequency modification, and will be returned to the customer with no action taken.

After the new crystal has been installed, the module is tested for nominal frequency

and trimmability at room temperature, overall frequency specifications over the

specified temperature range and RF output. If the module uses a compensation network,

ICM will make adjustments necessary to insure that the frequency drift due to

temperature does not exceed the original manufacturer's tolerances. Some modules have

the crystal and a few compensation components only, not the entire oscillator assembly;

in these cases the unit is spot checked using an oscillator of the required type. In

addition, some modules such as offset type units are actively modulated; these units

are set up on a test fixture and tested to insure proper deviation.

|

Go to the Tech Index page

Back to Home

Text, HTML and copyright © 2007 and date of last revision by Mike Morris WA6ILQ (callsign) //at// repeater-builder

//dot// com

Text copyright © Repeater-Builder.com 2002, 2004, 2005, 2007, 2009.

This page originally posted on 01-Febuary-2007.

This web page, this web site, the information presented in and on its pages and

in these modifications and conversions is © Copyrighted 1995 and (date of

last update) by Kevin Custer W3KKC and multiple originating authors. All Rights

Reserved, including that of paper and web publication elsewhere.